Basic HTML Version

72

This training program provides

an introduction to the complex

subject of safety engineering in

industrial machines and systems.

The aim is to make participants

more aware of the problems in

the design aspects of safety

engineering and help them

understand safety engineering

equipment and hazard analysis

methods.

The training program is based

on an amended version of the

EC Machinery Directive

2006/42/EC, which came into

force on 29 December 2009.

Until then, 98/37/EC was valid.

There is no transitional period.

How is the overall performance

level of a technical safety

measure determined? The

training program explains

concepts such as probability of

failure (POF), diagnostic

coverage (DC), common cause

failure (CCF), redundancy and

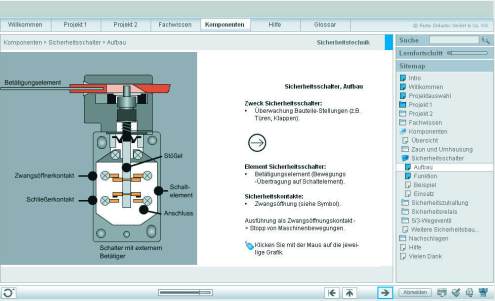

diversity. There is also a detailed

explanation of all the

components for safety

equipment.

From the contents

• Introduction to machine safety

• The question of liability (who is

liable in the case of an

accident?)

• European directives

• The relationship between

directives and standards

• The new EU Machinery

Directive 2006/42/EC

• The hierarchy of the European

standards for machine safety

• Machine safety in the USA

• Risk assessment procedure

according to EN ISO 14121 and

EN ISO 12100

• Definitions

• Risk estimation: determining

the Performance Level required

• Risk reducing measures:

design measures, technical

safety measures, instructive

measures

• Selecting the safety function

• Determining the control

category

We can meet your needs

Available as a CD-ROM version

or alternatively a WBT version

for installation on networks and

learning management systems,

with as many licences as you

need.

Duration

About 4 hours

For more information, see the

Festo Didactic homepage:

www.festo-didactic.com

WBT – Web-based training for safety engineering