Basic HTML Version

21

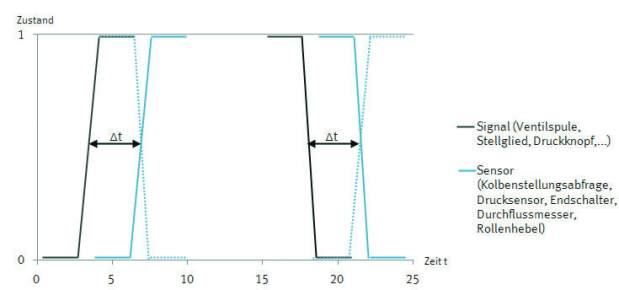

A plausibility check reveals

faults with different causes

• Solenoid coils, final control

element or pushbutton

generate a signal

• Energy switching element,

a valve in this case

Change of status

• From 0 to 1 or

• From 1 to 0

Sensors

E.g. piston position sensing,

pressure sensor, proximity

sensor, displacement encoder or

flow meter must register the

change of switching status

Pneumatic diagnostic options

Plausibility check

The PLC checks whether a signal change has taken place within a

specific period t, and if the desired change in status has occurred.

Plausibility

check t

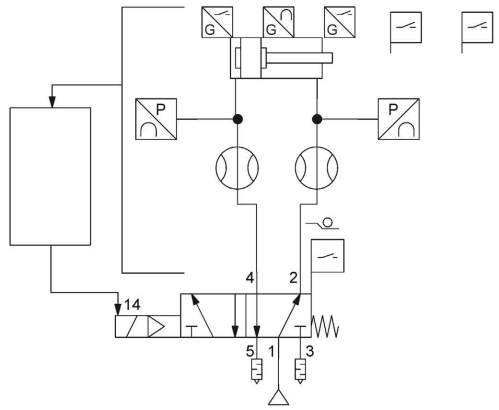

Proximity sensor (S1, S2)

Output signal

PLC

Displacement encoders

Pressure

sensors

Flow meter

Switching position sensing

Status

Time t

Signal (solenoid coil, final control

element, pushbutton, etc.)

Sensor

(piston position sensing, pressure

sensor, proximity sensor, flow

meter, roller lever)