Basic HTML Version

63

See the technical data of the individual products for detailed information.

Please observe the legal information on page 73.

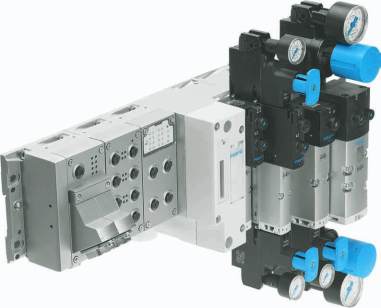

Creating pressure zones and

separating exhaust air

• With the VTSA, pressure zones

with different working

pressures can be easily

created

• A pressure zone can be created

by separating the internal

supply ducts between the

series manifolds using

appropriate duct separation

• Compressed air supply and

exhaust via the supply plate

• Free positioning of the supply

plates and separating seals in

the VTSA

• Channel separations

integrated ex works as per the

order, differences can be

indicated via the coding

system for assembled valve

terminals

VTSA with CPX terminal

connection

• Up to 16 pressure zones

possible with VTSA

(if only size 1, ISO 5599-2,

is used, up to 32 pressure

zones are possible)

Further examples of pressure

supply and pilot air via an

end plate

• Internal pilot air, ducted

exhaust air/silencer

• External pilot air,

silencer/ducted exhaust air

Reliable exhausting of valves

or pressure zones

If used together with the MS6-SV

valve, certain areas can be

exhausted safely whilst the

pressure is retained for specific

valves or pressure zones.

This is a common requirement

for protective circuits.

Pressure zones for valve terminal type 44 VTSA

The illustration shows an example

of how three pressure zones are

built up and connected with duct

separation, with internal pilot air.