12

Digital simplicity: World first Festo Motion Terminal VTEM – Subject to change – 2017/11

Areas of application for the Festo Motion Terminal

Always ready to go:

the successful, tried-and-tested

electric automation platform

CPX. With CPX, you can integrate

the fieldbus or Industrial

Ethernet nodes you need, plus

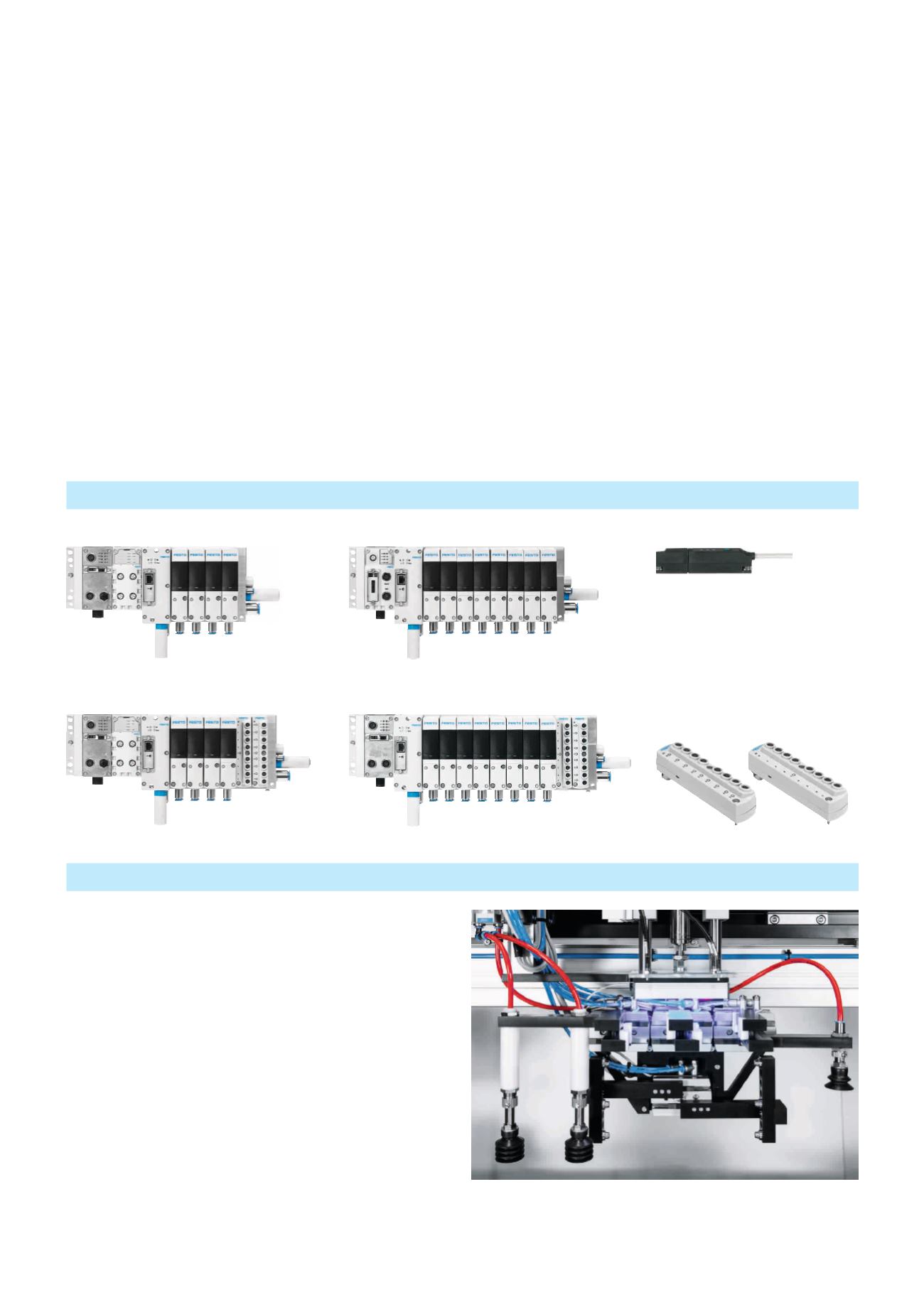

1. Pre-positioning, gripping with

controlled vacuum and setting

down with ejector pulse

Motion Apps: Proportional

pressure regulation. Available

in 2018: Motion profile and

positioning. The different formats

required for this task often

involve adjustments and,

depending on the solution used,

several components. The

gripping vacuum and ejector

pulse need to be regulated and

checked individually for every

format change-over.

additional I/O modules, subordi-

nate installation systems such

as CTEL, or CODESYS controllers

with an OPC UA interface. The

two automation platforms are

the perfect partners.

The advantages in detail:

• 7 fewer components

• 75% less installation space

• Identical costs with significant

process improvements

• Faster format change-over

(−20 minutes per change-over),

plus always the same settings

• In the future, gripper formats/

reduced cycle times can be

easily expanded

What areas offer the perfect environment for the Festo Motion Terminal as a pneumatic automation platform?

What variants are available? Here are a few application examples. More will follow soonA

Application examples

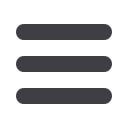

Here is an overview of the available variants:

Platform with 4 valves

Platform with 4 valves and 2 input modules

Platform with 8 valves

Position transmitter SDAP

Platform with 8 valves and 2 input modules

Input modules CTMM:

analogue and digital

50 mm