4

Digital simplicity: World first Festo Motion Terminal VTEM – Subject to change – 2017/11

Revolutionary: one valve technology for a huge range of functions

The new valve technology of the Festo Motion Terminal can be used for a wide range of products, functions

and complete solution packages. The only prerequisite is a valve design with multiple degrees of freedom for

actuation, as well as integrated data acquisition and processing suitable for a cyber-physical system. The

reduction to just 1 valve variant provides both system builders and operators with huge economic benefits.

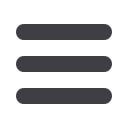

• Four 2/2-way valves

(diaphragm poppet valves)

are connected in series to

form a full bridge

• Each diaphragm poppet valve

(grey) is proportionally piloted

and controlled by two piezo

valves (blue)

• Sensors monitor the stroke

of each poppet valve, while

pressure sensors monitor

the pressure at ports 2 and 4.

All four pilot cartridges

(blue) form a total of eight

proportionally controlled

2/2-way valves.Thanks to

the integrated sensors and

proportional control, which

allows the valves to be

pressurised and exhausted

independently, this single

valve technology can now

be used to execute a wide

range of conventional valve

functions and full system

solutions, such as Soft Stop

(available Q3/2018).

1 valve variant: a single valve

replaces over 50 individual

components

The bridge circuit in the valve

of the Festo Motion Terminal is

an innovative valve system that

is based on the basic elements

of pneumatic valve functions.

U

U

P

P

2

4

1

3

2 4

1 3

2

4

1

3

2 4

1 3

2

4

1

3

2 4

1 3

Flow/pressure

port 2

Flow/pressure

port 4

Piezo pilot valve

2x 2/2-way valves in one

cartridge

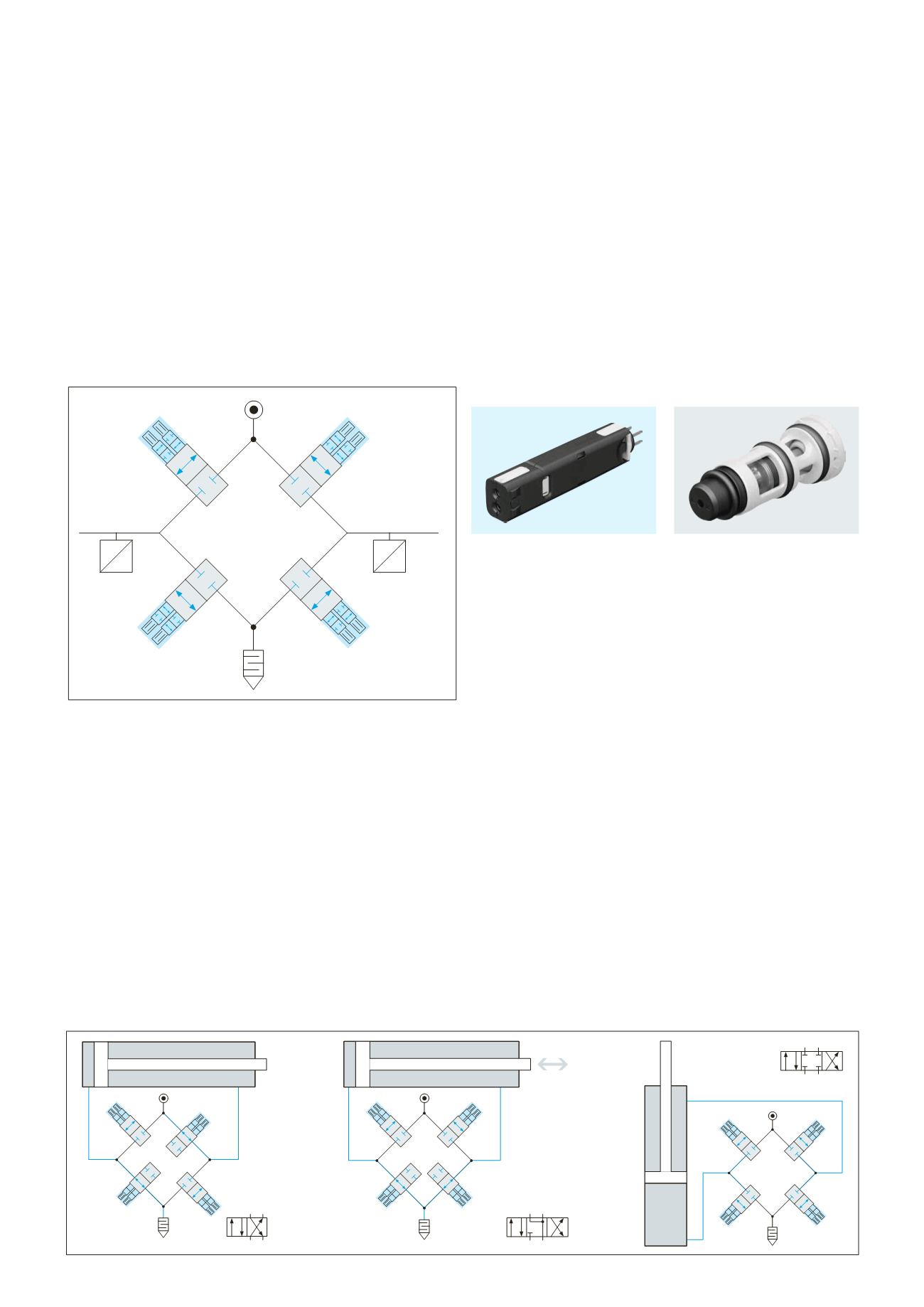

From simple directional control valve functions to complex motion tasks

Diaphragm poppet valve

Bridge circuit in the valve