Aspreciseasa

Swisswatch

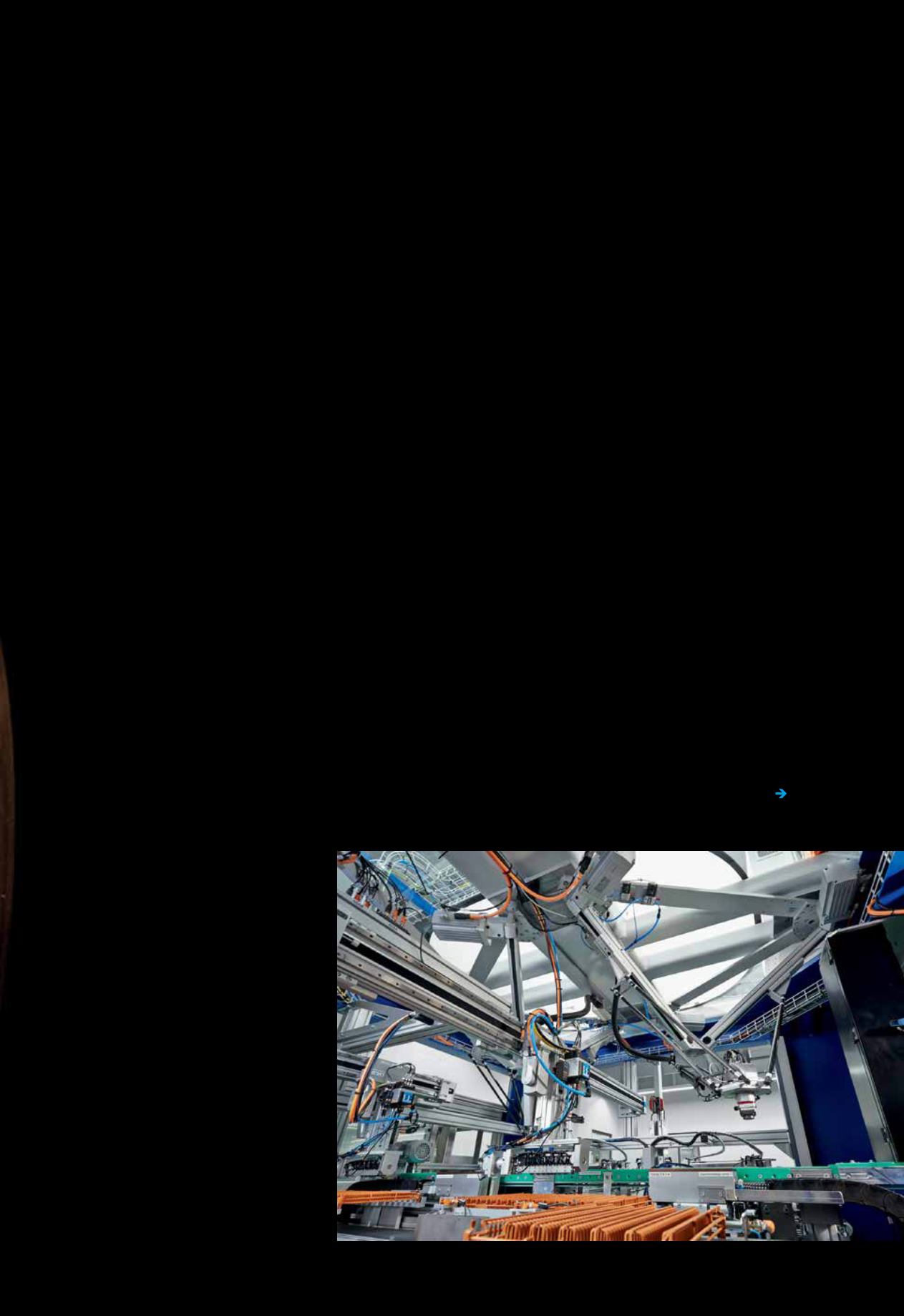

Faster palletisingwith thedelta robot EXPT

TheSwisswatch industryprotects the

legendary reputation

of itswatcheswith

thequality label “SwissMade”. This level of quality canonlybeachievedwith fast

andaccurateautomationequipment. This ledAmaxAutomationAG to createa

multifunctional palletiser –with roboticandhandlingsystemssuchas the ready-

to-install delta robot EXPT from Festo.

A

ccording tosurveys, consumers

fromall over theworldare

willing topayup to50%more

for awatch if it carries the

quality label “SwissMade”.This label also

means, according to legislationby the

Swissparliament, that in termsof

production costsmore than60%of these

finewatchesmust havebeen

manufactured inSwitzerland.

This isoneof the reasonswhy theSwiss

watch industry is carryingoutmoreand

moreof theproductionsteps forwatches

andwatchparts inSwitzerland. Another

reason is that risingwage costsare

making thesuppliers in lowwage

countries lessand lessattractive. Coupled

with this is the fact that these countries

often cannot attain the reproducibility

required for sophisticated, handmade

parts. Therewerealsoquality lossesdue

to theprecisionstampedpartsbeing

handledasbulkmaterial. This led tomore

wastageandhigher cleaning costs.

Byproducing in itshomemarket, the

Swisswatch industrybenefits from faster

andshorter transport routesandsimpler

production control. Thepalletisers

suppliedby theSwissspecialmachine

builderAmaxensureaccuratelysorted

andpreciselystampedparts for further

processingsuchaselectroplating,

painting, padprintingandassembly. The

highprecisionpartsaredifferent for each

watchmodel andeachbrandandare

extremely thin,witha thickness in the

rangeof tenthsof amillimetre.

Maximumaccuracy

Themultifunctional palletiser isvery

flexibleand fast.Witha throughput of 120

partsperminute, it canset downup to

elevendifferent small parts insixdifferent

lattice traysor twodifferent JEDEC trays.

Maximumprecision

is requiredwhen inserting thewatchparts.

Themachine canbeeasilyset up for other

partsvia teach-inusing the control panel

and thesoftware. Thesubsequent steps

in theprocess require theparts tobeset

down in the trays toahighdegreeof accur

acy. Thepartsmust alwaysbe right side

up in the trays. Two integratedvision

systemsandaspeciallydeveloped

turningsystemensure that only correctly

orientedpartsareset down.

Issue27

trends inautomation

Synergies

28

–

29