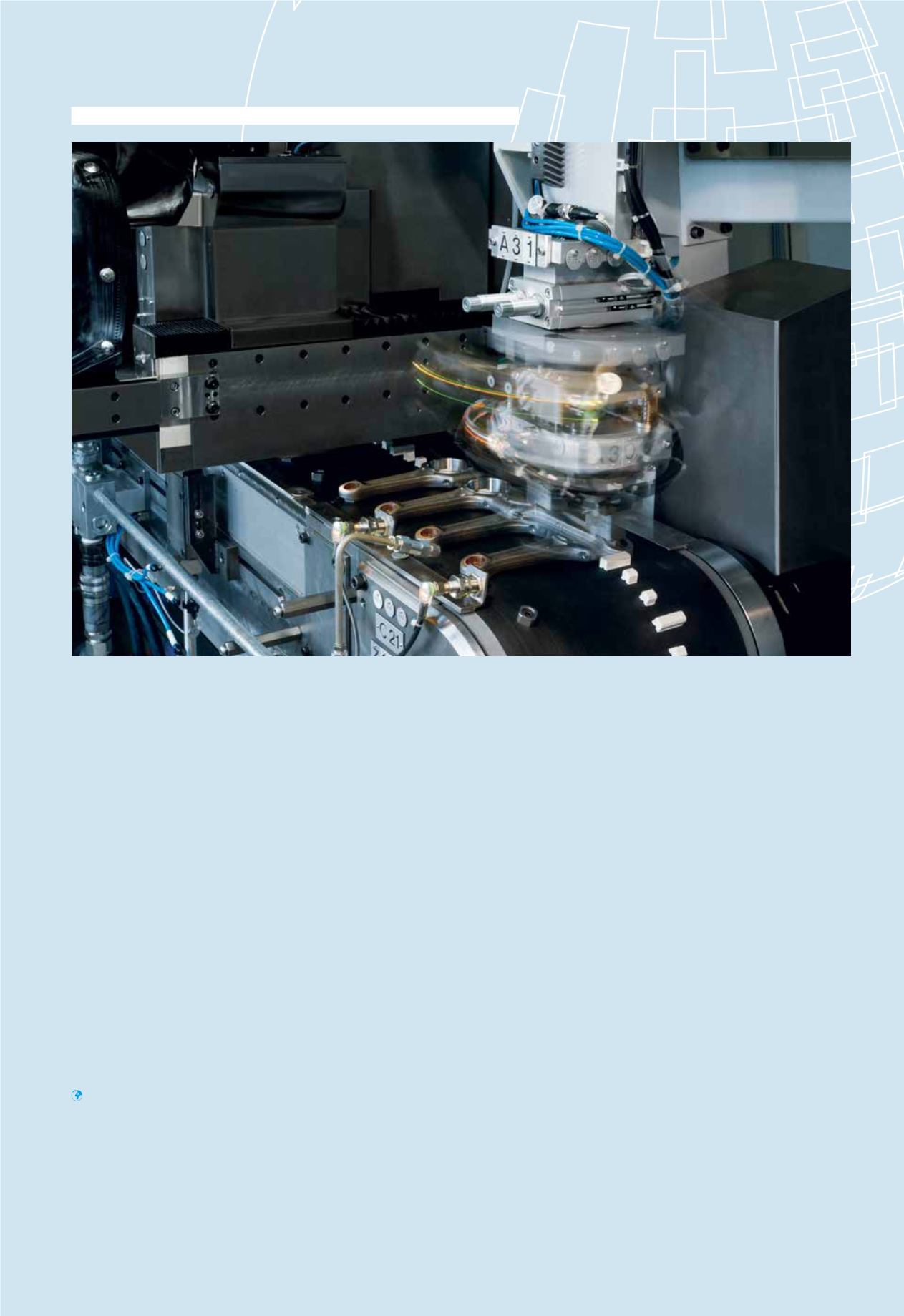

TheDRRDovercomes themoment of

inertiaof themassivesubstructure

withhighdynamic responseand force

thanks to itssturdybearing.

Switzerland

It

’

sall about inertia

Reliablemachiningof con-rods

The componentsused for highspeedgrindingmust beverypowerful anddurable.

Swiss companyLinearAbrasiveSA thereforeuses thesemi-rotarydrivewithpiston

DRRD from Festo for itsautomatedhighspeedgrindingmachines.Themachineswork

onvariousconnecting rods from threesides,with the infeedandoutput of the

workpieces fullyautomated.

In thepast, the ingressof cuttingandgrindingoil regularly resulted inpremature

failureof thedrives. Using theDRRDmade theprocessmorestable. Aftermore thansix

monthsof continuoususe in threeshift operation, thesemi-rotarydrivewithpiston

fromFestoshowsnosignsof fatiguedespitebeingexposed toaggressiveoils. The

innovativebearing concept of theDRRDmakes it sturdyandstable, allowing it to

handle the largemomentsof inertiawithout anyproblem.

Aswell ashigh repetitionaccuracy,whichdidn’t require readjustment evenafter

assembly, theDRRD isalsodistinguishedby itsspeed. It effortlesslysurpasses the

required5.8s cycle time formachiningeach connecting rod.

Issue27

trends inautomation

Festoworldwide

38

–

39