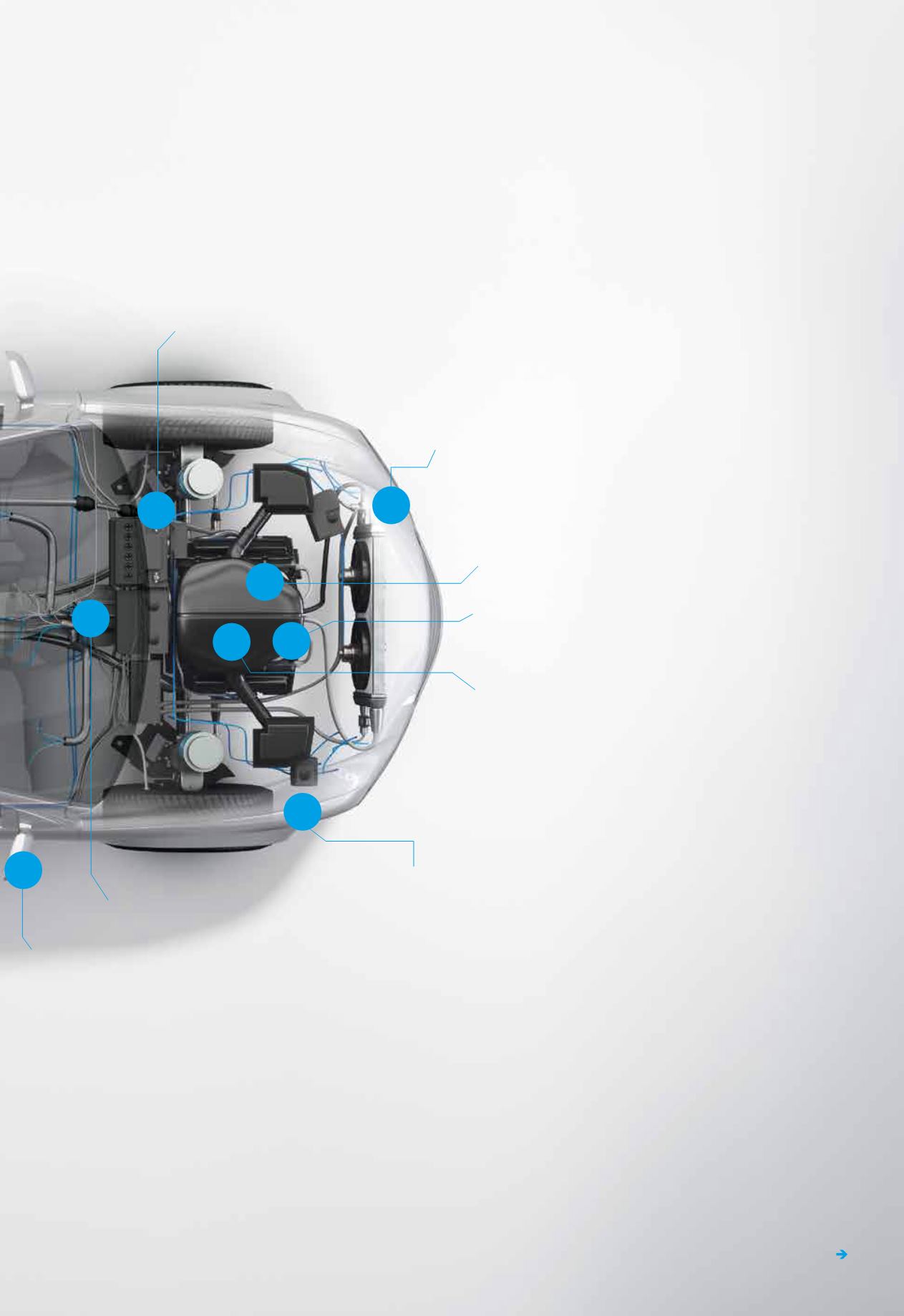

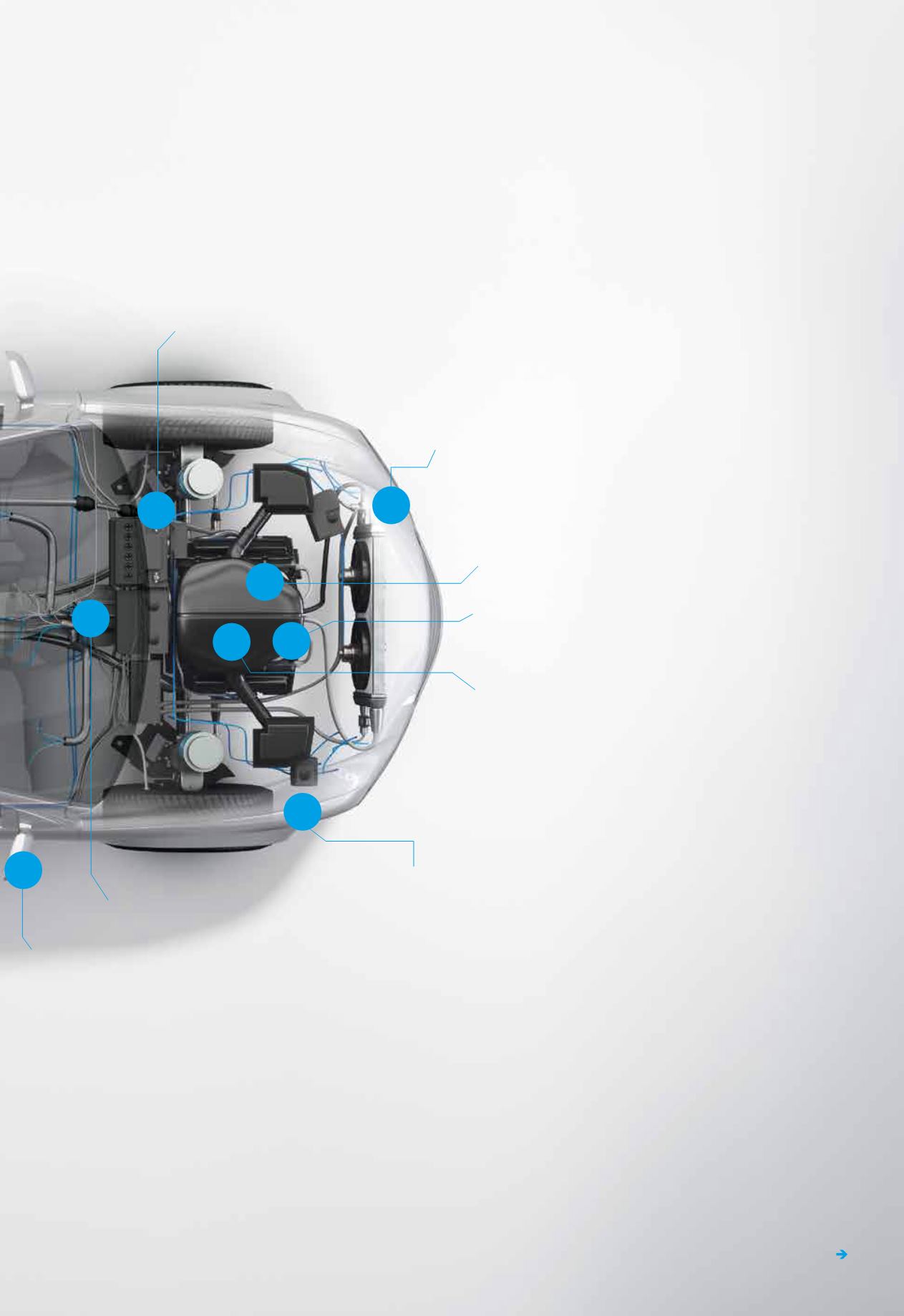

Outside temperaturesensor

Lanedeparturewarningsensor

Camshaft sensor

EGRvalvesensor

Steeringanglesensor

Blindspot sensor

Transmissionsensor

Temperaturesensor

T

hesedays, a car ismuchmore

than just ameansof getting from

A toB. It canalsoprovide

intelligent feedback thanks toall

kindsof comfort andsafety functions. The

typical car todayhasonaverageup to

100sensorsonboard,with thenumber

set to increase further in the future.With

thenumber of sensorson the risebut the

availablespacestaying thesame,more

compact and insome casesalsomore

robust sensorswill be ingreater demand.

Innovativeproductionsolutionsare

needed inorder for theproduction

process tokeepupwith this level of

sophistication. Belgiancompany IPTE

FactoryAutomationn.v. hasmet thenew

challengeheadonwith its latest systems.

Theexperts in factoryautomationworked

with Festo todevelopan innovative

machineconcept for theselective

solderingof sensorsdirectly in the

housing.

Reliablesoldering in thehousing

Sensors locatedoutside the car’s interior

have towithstandharshenvironments,

with temperatures ranging frombelow

-40 °C toover 100 °C, and theyalsoneed

tobecorrosionandshock resistant.These

sensorsareenclosed ina toughhousing

toprotect them.However, the inner parts

of thesensor cannot be inserted into the

housing fullypre-assembled. Certain

solderingworkhas tobedonedirectly in

thehousing. Conventional soldering

techniquessuchaswaveor reflow

solderingarenot possiblehere, since the

plastichousingwouldnot beable to

withstand the temperatures involved.The

onlyoption is themoredemanding

techniqueof selectivesoldering. An

essential requirement for this technique

isapplying the right forceat the right

angle. Thehighprocessquality, repetition

accuracyandproductionspeedneeded to

achieve this calls for fullyautomated

processes.

Development of anewmachine concept

IPTEdevelopedanew, programmable

selectivesolderingsystem for connecting

thebatteryandprinted circuit board

directly in theprotectivehousingof the

car sensors. A completemachine concept

was created for this in cooperationwith

Festo. The ready-to-install handling

systemby Festoenablesa cycle timeof

less than threeseconds throughquick

andprecisemovementsalong theX-,Y-, Z-

andW-axes, despiteamovingmassof

more than60kg. Thesolder is fedwithan

accuracyof 0.1mmand thespeedat

which thesolder isuncoiled from the reel

is controlled.Other advantagesof the

compact IPTEsystem includeautomatic

tip calibration, integrated tip cleaning,

operationwithsolder reels, colour

detectionandanoption toswitch to

unleadedsoldering. A reliablesuspension

systemensures that thesoldering tip is

applied to theprinted circuit boardwith

the right force for optimum thermal

contact duringsoldering. An integrated

The typical car todayhasonaverageup

to100sensorsonboard. Sensors located

outside the car interior, ofwhichaselection

canbeseenhere, needspecial protection

anddemandspecial productionmethods.

Issue27

trends inautomation

Synergies

32

–

33