“Festo’sproportional technologymakes

our thermoformingsystemseven faster

andgentler on thematerial.”

ArndZander,HeadofDesignatMaschinenfabrikHerbertMeyer

(A)

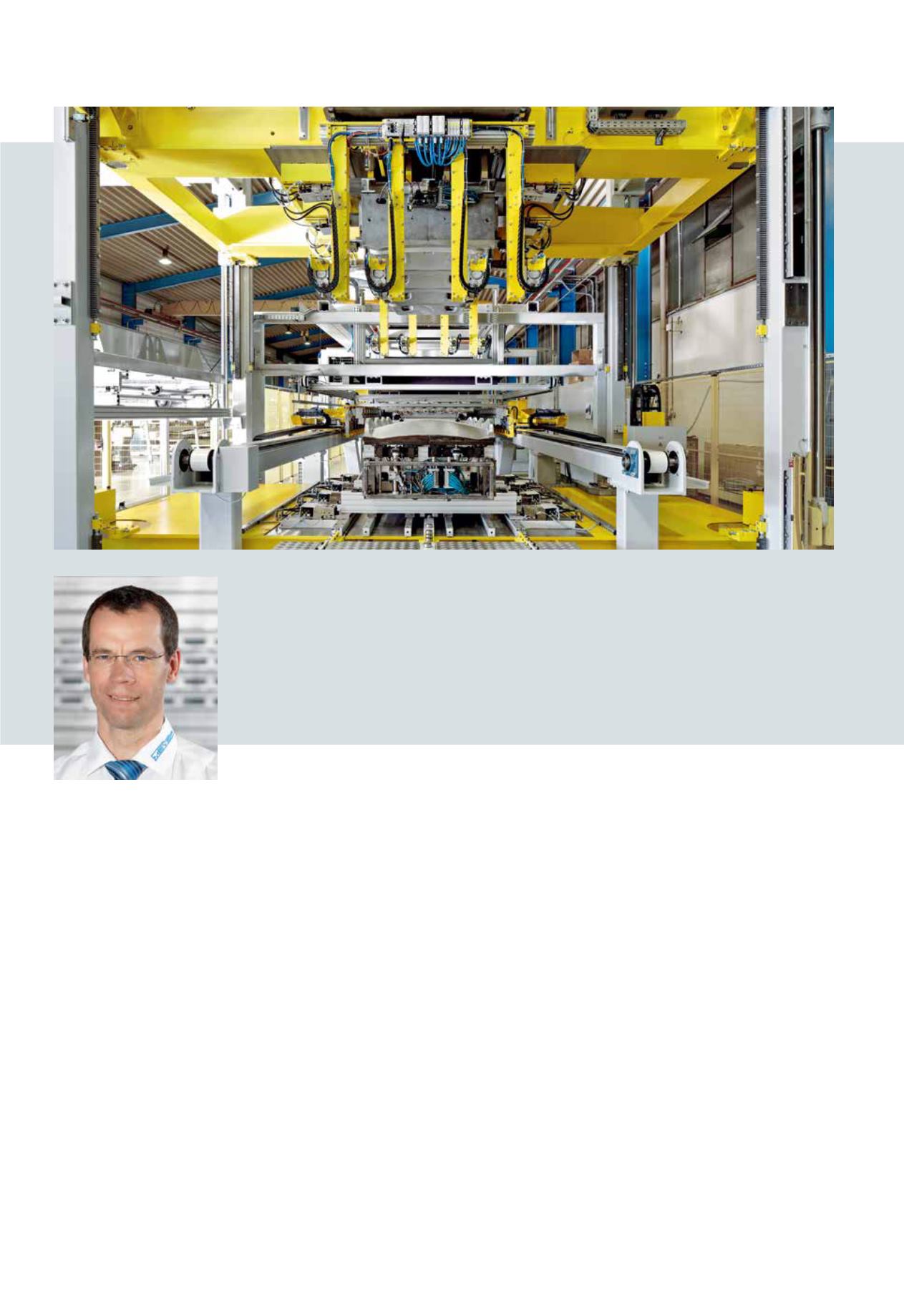

andbelow. From there, theblanksare

transferred fullyautomatically toa feed

tableheatedby90 °Cwater.A radiant

heater locateddirectlyabove this table

brings theblanks to their final processing

temperaturewithout any contact. The

flexible combinationof contact and

radiant heat enablesdifferentblank types

tobeheated in themost suitableway,

thusavoiding theproblemof unsightly

pressuremarks.Once theblankhasbeen

uniformlyheated comes themost

important step: thermoforming. For this

step, themain conveyor picksup the

blankusing its24grippers–eight per

sideand four each in the infeedand

outfeedarea–andpositions it on the

lowermould. Theuppermould is then

dropped, pressing theblank into itsfinal

shape. After pressing, themouldsopen

againand themain conveyor transfers the

blank toabeltmovedbya rodlessdrive

DGC-K for coolingand further processing.

Movingasgentlyaspossible

Everygripper on themain conveyor has

four degreesof freedom, canbeopened

and closed individuallyandapproached

verticallyandhorizontallyusing

proportional valves. Thisallows the

system toadjust flexibly todifferent blank

sizes.

A further cylinder typeDGC-K isusedon

thevertical axis. Itsfloatingposition

ensuresperfect adaptationof thegripper

to themould’scontour.Thegripper reacts

flexibly to the tensile forcesexertedby

themouldson theblankduring the

formingprocess. Thegrippers canalsobe

pivotedonanaxisof rotation in the feed

direction. Thisenables them to freely

track themould contour. Thebenefitsof

thisare twofold: firstly it ensuresvery

gentle formingof theblankmaterial

without anyweakspots, andsecondly it

doesawaywith theneed to reprogram

thegrippers for specificproductswhen

changingmoulds. All that needs tobe

adjustedare theblankdimensionsand

the tensile forces. Apositivesideeffect of

the increasedsystemprecision is reduced

material consumption. This isbecause

savingevena fewsquare centimetresof

floor coveringcanveryquicklyaddup to

severalmillioneuroswhendealingwith

thequantitiesused in theautomotive

industry.

Beingslimsavesmoney

Advancedproportional technology from

Festoenables thedrivesof themain

conveyor tomovewithdifferent pressures

dependingon themouldand theblank

material. Thevalve terminal CPX/MPA

permits fully independent adjustment of

the24 individual grippers.When the

product is changed, thesettings for the

specificmaterial andmouldare changed

at thepressof abutton. Thismeans that