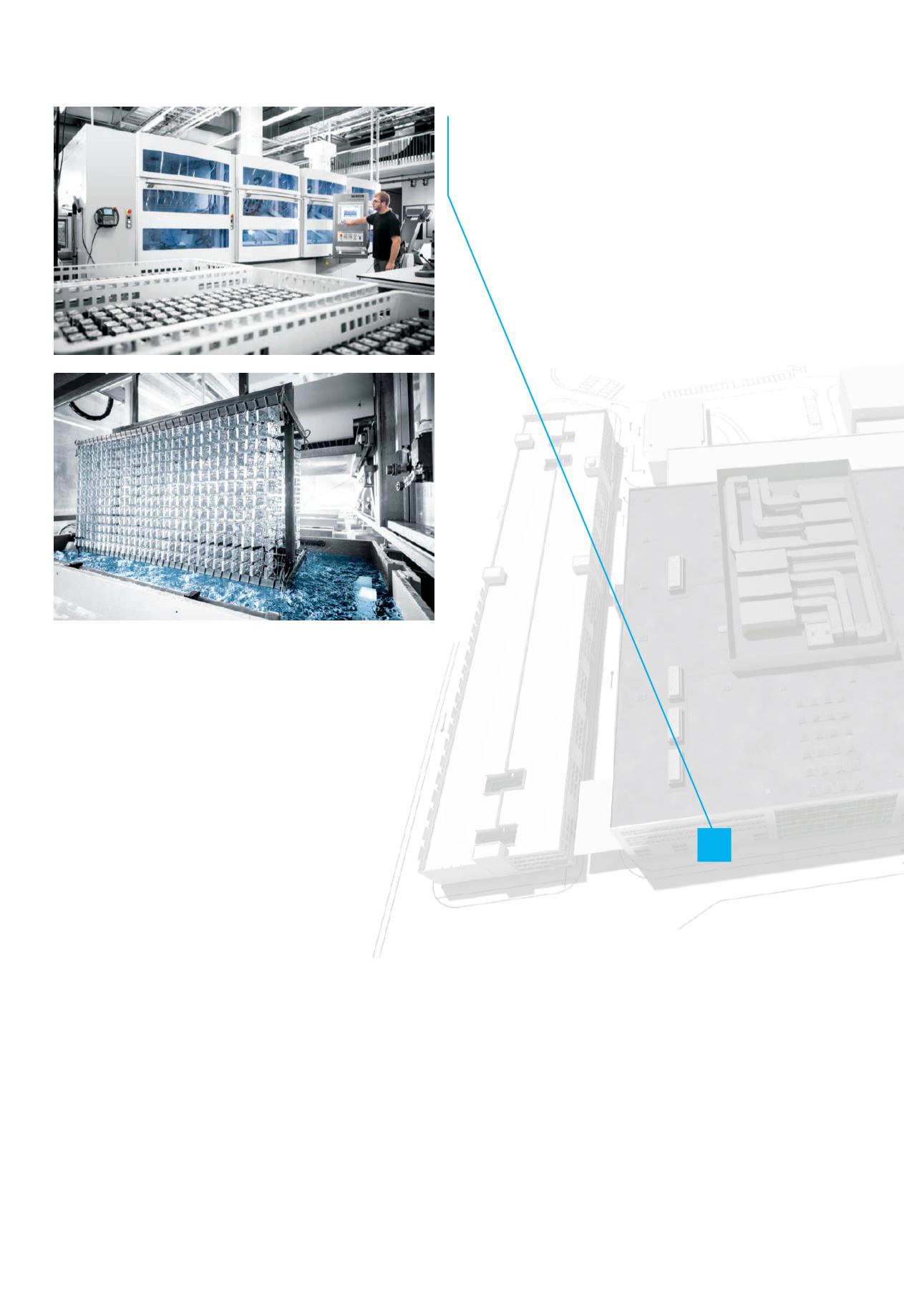

The components are immersed

in electroplating tanks

to give them the necessary surface properties.

place in a space measuring just 120

metres inside the Technology Plant. High-

quality products, valves and valve

terminals, electronic components and

customer solutions are thus produced

under one roof in a very short space of

time.

In perfect shape

The Technology Plant is divided into

four

areas: (1)

machining,

(2)

assembly,

(3)

electronics manufacturing and

(4)

customer solutions.

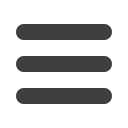

Metal-cutting machines weighing several

tons stand in an area covering 14,000

square metres on the ground floor of the

Technology Plant. Turning, milling, drilling

and grinding – in the machining

department, precision components made

of metal are manufactured for further

processing in the assembly process. The

production lines work around the clock to

produce the basic elements for Festo

products, such as valve housings and

individual components for linear units.

They produce millions of valve sealing

T

he new Festo Scharnhausen

Technology Plant symbolises

cutting-edge automation: 66,000

square metres, 1,200 employees,

a sophisticated, highly efficient value

chain, open communication with the

Learning Factory and creative think tanks.

Networked systems enable the first

Industry 4.0 technology solutions to be

created. Every day employees interact

directly and safely with a flexible robot.

Information and materials flow quickly,

flexibly and reliably in seamless value

streams.

Short routes

In the lean Technology Plant, the individual

manufacturing processes are linked to

each other by the shortest of routes. They

are arranged so that, as far as possible,

there is no need for interim buffering

across warehouse stocks. For example,

while some processes used to be

distributed across several plants over a

distance of 32 kilometres, they now take

Machining department with electroplating

In an area covering 14,000 square metres,

the

highly automated production lines work around

the clock to produce the basic parts for Festo

components.

1