Issue 30

trends in automation

Impulse

12

–

13

“The Multi-Carrier-

System anticipates

three trends of the

future: batch size 1

as standard,

flexibility in the

software and

intelligent, self

learning machines.”

Rainer Feuchter, Managing Director of Optima

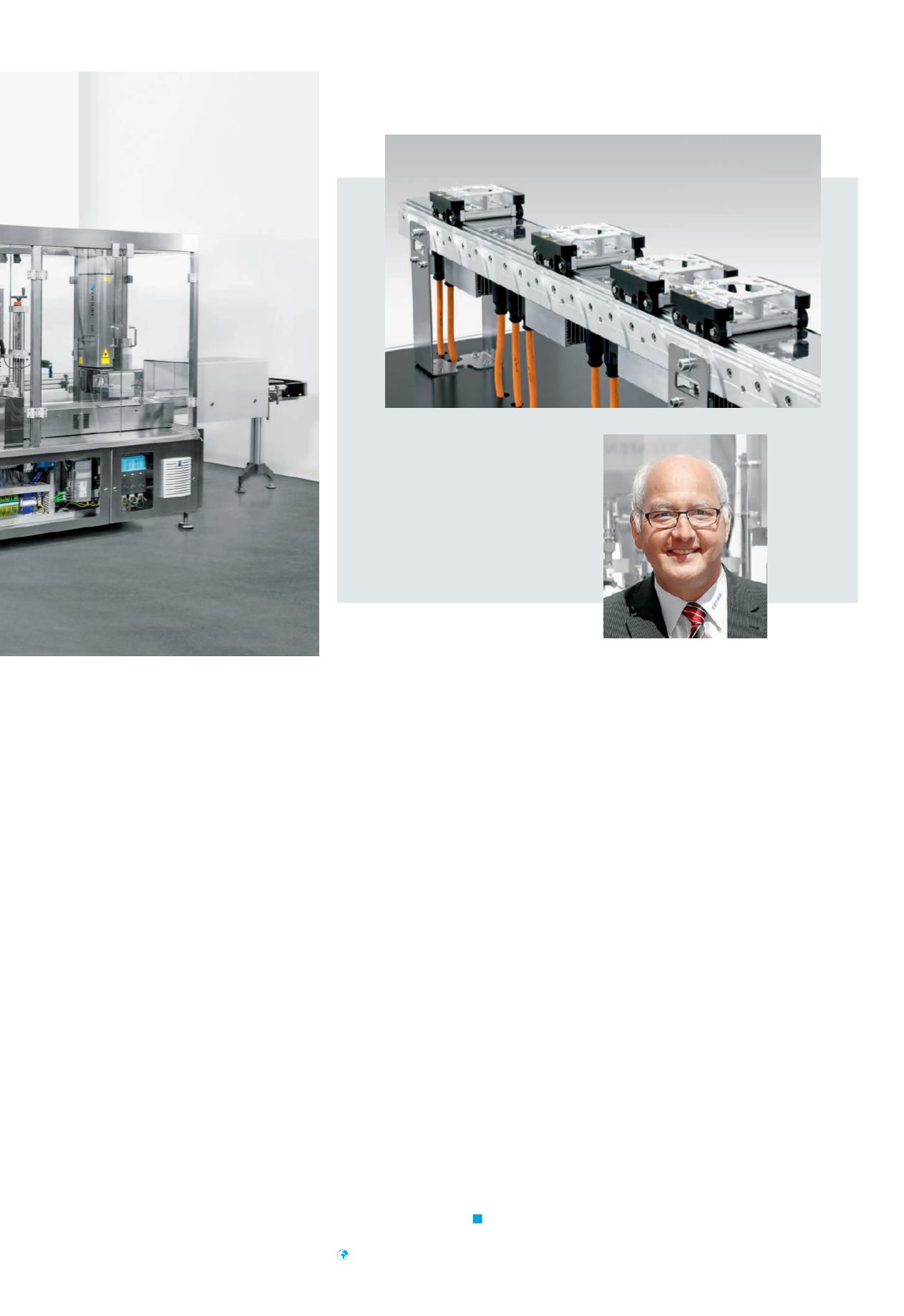

need to be filled, such as bottles, cans or

flacons, move one by one on carriers that

can handle multiple formats and are

individually actuated. The self-propelled

carriers are driven by linear motors. In

order to avoid jams, they move according

to the rules of swarm behaviour and in

synch with the process – either

individually or in groups. The carriers can

be freely and seamlessly fed in and out of

the Multi-Carrier-System. Linking to an

existing intralogistics system couldn’t be

simpler. The carriers can be accelerated,

slowed down and freely positioned,

independently of one another. Thanks to

integrated RFID chips, they carry all the

information that the machine needs to

produce the end product. As a result,

single-unit productions are thus,

mechanically speaking, possible.

The Mult-Carrier-System in action

The Optima packaging machine comprises

three modules: filling, closing and laser

engraving. The modular machine design

requires flexible transport: the machine

can fill six bottles during transport and

subsequently seal two of them at the same

time. This means that carriers need to

move in groups of two so that production

can continue without pile-ups. For

customised laser engraving, the system

requires only one carrier – something that

can be easily achieved with the Multi-

Carrier-System.

The possibilities are endless

The Multi-Carrier-System travels at up to

3 m/s and achieves acceleration of up to

40 m/s² – completely jerk-free and with

optimum precision. Shorter set-up times,

reduced maintenance costs, lower rates

of wear, and the ease of cleaning are

further advantages of this versatile

transport system.

The potential applications of the Multi-

Carrier-System are practically unlimited; it

is suitable for all industries that manage a

large product diversity. These include the

cosmetics industry with its huge number of

product variants, the food and drinks

industry with its quick seasonal changes

and industrial manufacturing of one-off

products ordered by end customers using

an online configurator.

www.festo.com/mcsLinear motion control

enables

format adjustment at the push

of a button.

Application example:

Optima

filling and packaging machine.