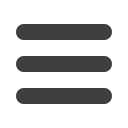

Human-machine interaction

Many of the aspects of Industry 4.0 – such as

human-machine interaction – are already a reality

in the Scharnhausen Technology Plant. The

assembly robot grips housings, joins cartridges

and frames together and passes the component on

to a worker for further processing. Such teamwork

poses no risk for the individual. Sensors

continuously monitor all the robot’s actions. It

does this thanks to a specially developed plastic

“skin” fitted with highly sensitive sensors. As soon

as an employee comes too close to it, the robot

slows down or just stops. Thanks to effective

safety mechanisms, the robot does not have to be

behind bars.

“The Scharnhausen Technology

Plant has flexible, highly

automated and energy-efficient

production processes.”

Stefan Schwerdtle, Head of the Global Production Centre Scharnhausen

An employee works

with the assembly robot

in an intuitive and safe manner.

valves from the VUVG series. Here, eight

production cells spread over 30 metres

operate in sequence. Several million

valves can be assembled annually, with

cycle times of less than 15 seconds. Many

of the company’s own products and

solutions are used here. In other words,

Festo products are used to manufacture

Festo products. Each line produces over

50 individual variations of different sizes,

with 20 variations making up over 80 per

cent of the total volume.

Manual work is still required when it comes

to assembling the valves into valve

terminals as well as for special solutions

and single components for individual

customer needs. Quantities vary from a

few thousand a year or a small batch of

several hundred to just a single item. For

some products, which have to be made

according to individual customer

specifications in a very short space of

time, there may be as many as 10

40

variations.

Electronics included

Many products simply wouldn’t exist

without electronics. In the Technology

Plant, 200 employees produce complex

electronic assemblies and products in an

area covering 6,000 square metres. 2.5

million of them are produced each year

for use by the company itself. The areas

responsible for further processing receive

either complete assemblies in their