AuEKasselGmbH

Heinrich-Hertz-Str. 52

34123Kassel

Germany

Areaof business:

Automationspecialist for all

productionwork relating toaxles,

chassisandsimilar tasks

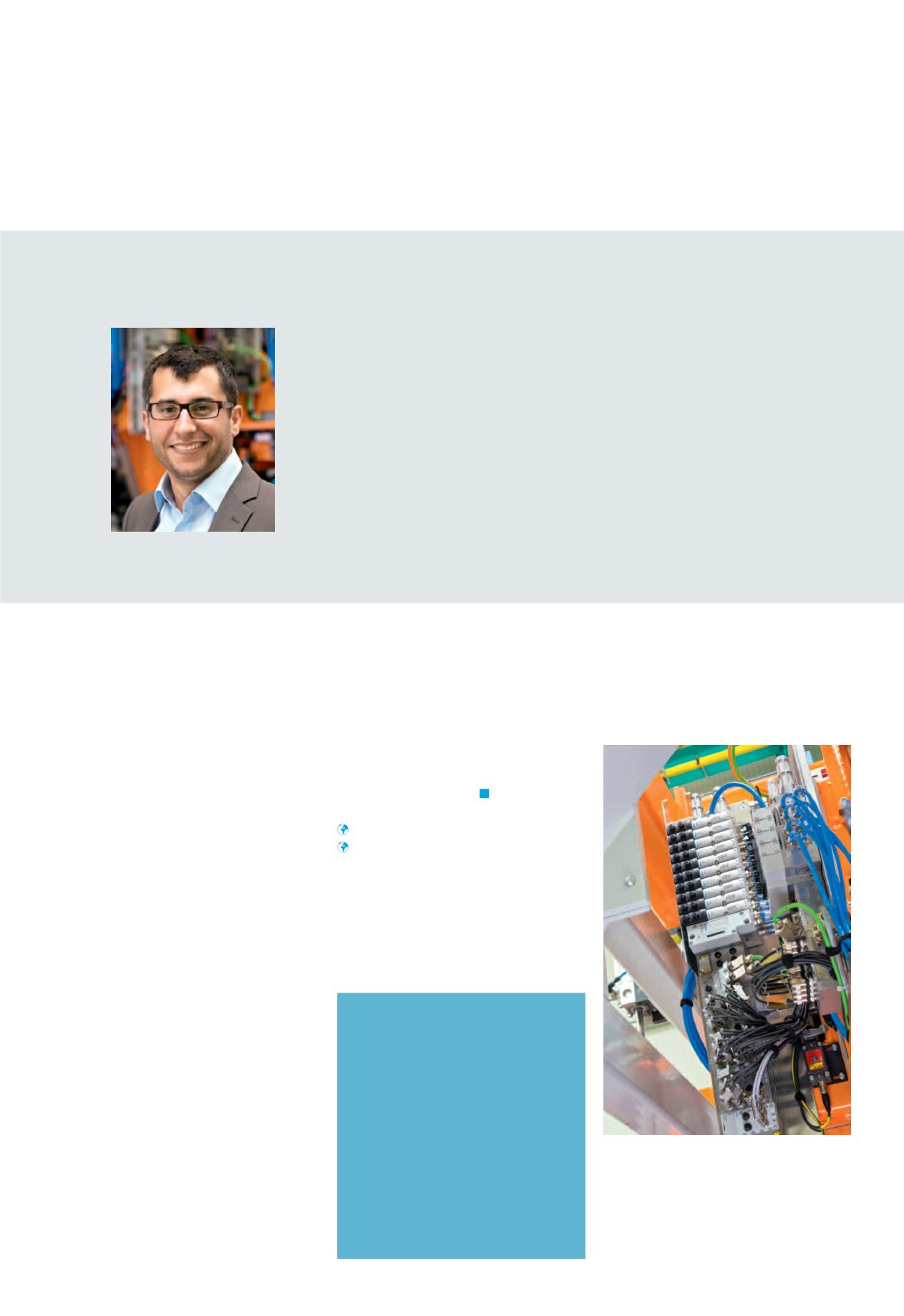

Tokeep tubingandwiringeffort

toaminimum,

theCPX-VTSAvalve terminalsareattacheddirectly

to the lifting frameof thesystem.

“Thanks to theFestovalve terminals

wehavebeenable to reduce the

installationand tubingeffort in the

system toaminimum.”

ValerioLoi, ProjectManagement, AuE

the relative futurepositionof thewheels

automaticallyusing theprobes. Thead-

justing toolsadjust the trackand camber

values in real timeand counterwith the

final screwing torque.The tools thenmove

awayand theaxle isplacedbackon the

workpiece carrier. Thesystem references

itself comparedwithamaster gauge in

specified cycles.

Toavoidhaving to interrupt theproduction

processduringmachinemaintenance, the

machine canbemoved from the conveyor

technologyarea toaspecially created

maintenanceareavia racksandguide rails.

Intelligent supply

Aspecial featureof thenewmachineare

thevalve terminals installeddirectlyon

lifting framesandvertical slides; this

reduces theeffort required for tubingand

wiring toaminimum. The lifting frame

that picksup theaxlehas twoVTSAvalve

terminalswithCPX inputmodules, separ

ated into the left and right side. In thever-

tical slide,which carries thehubgripper,

thereare twosmallerVTSAvalve terminals

with four valveseach,which control all

theactuatorsbeneath theenergy chainof

theslide. Thanks to thissolution, asupply

tube, apower supplyandabussystem

areall that areneeded.

1.2015

trends inautomation

Synergies

32

–

33