KiefelGmbH

Sudetenstraße3

83395 Freilassing

Germany

Areaof business:

Developingandbuilding

systems for thermoforming

and joiningpolymer films

“With theVFOFwehave reduced

assembly timeand installation

space. Insteadof threeparts,we

nowneed to install onlyone.”

Peter Kronawitter, PneumaticsDesignEngineer, Kiefel GmbH

Fromfilm tobag

Although the individual systems fromKiefel

areall used toproducedifferent products,

the fundamental automationprinciple

behind themedical technologymachines

is thesame.Theprocess isbest illustrated

byanewsystem formanufacturing infu-

sionbags. In thefirst step, thefilm is

unrolled. Dancer rollersperformabuffer

function to cushion thesynchronised

motionsequences. They isolate thepower

from themachine,which isneeded toset

theparent roller inmotion.This is followed

by contactlesselectrostatic cleaningof

thefilmandapplicationof theproduct-

specific information in theprintingstation.

Thesystem laterally feedsafilmwith the

printmedium. The inlet andoutlet tubes

for fluidssuchasbloodor infusionsolu-

tionsare thenweldedon. In thenext pro-

cessingstep theentirebag isweldedand

the coolingsystems then reduce the tem-

peratureof theweldedsections. Finally,

thebagsareseparatedbypunchingor

cutting, placedona conveyor and trans-

portedonwards.

Three functions, onevalve

Until ayear ago, twopneumatic control

elements– theone-wayflow control valve

GRLAand theshut-off valveHGL–were

still requiredonmany cylinders. TheGRLA

wasused toadjust theflow rate,while

theHGLblocked theflow inonedirection.

Theblocked connection couldbeopened

againbya control signal. Bothvalvesare

still installed insystemswhere called for

by thedesignspecifications. Inotherareas,

however, the compact,multifunctional

valvesVFOF-LE-BAHareused. Thenew

components integrate three functions:

variablepistonspeed, short intermediate

stopand individualmanual exhaust. The

efficient control element thereforesaves

timeandmoneyand reduces the installa-

tionspacebyover50per cent. It iseasy

tooperateandassembleand canbe

usedeverywhere. Thepneumatic control

elementsoffer versatile functionality, are

energy-efficient andnon-polluting, and

reduce compressedair losses.

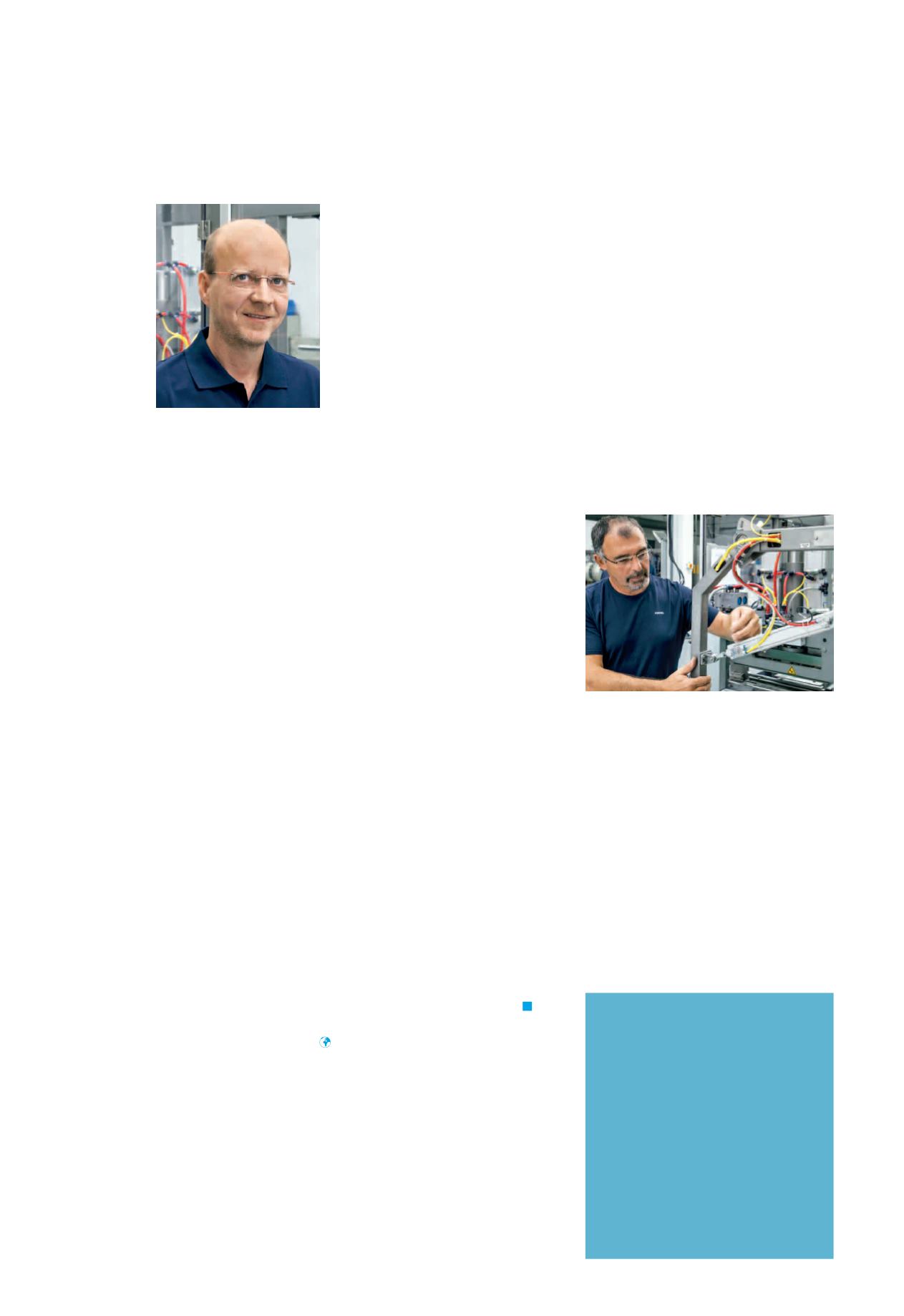

Two-thirds lessassembly time

For Peter Kronawitter, PneumaticsDesign

Engineer at Kiefel, useof thevalves

VFOF-LE-BAHhaspaidoff right down the

line. “Previously, our installation techni-

cianshad to install up to threedifferent

parts.Now they install just onepneumatic

component. Assemblynowonly takesa

thirdof the time that it used to”, explains

Kronawitter.Healsoseesbenefits for his

company in theextensiveportfolioof Festo

pneumaticproductsand in the fast,world-

widesparepartsdeliveryservice. “This

haspermanently reducedourwarehousing

requirements”, hesays.With theone-way

flow control valveVFOF-LE-BAH, Festohas

openedupnewpossibilities in termsof

timeandspacesavings for Kiefel.

Easy toadjust:

simpleadjustment

of the cylinder speed.