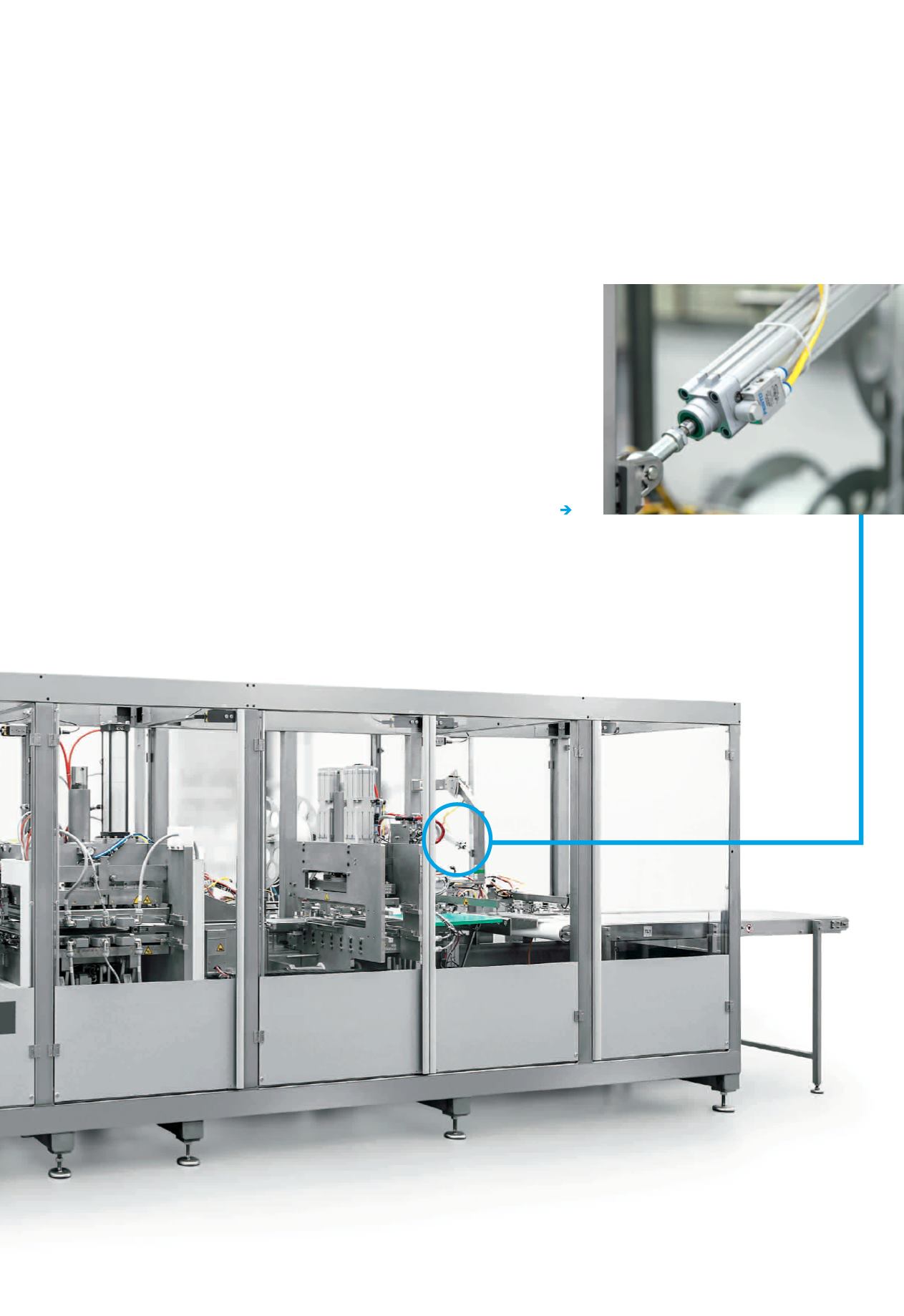

Fast andprecise:

thesystem formanufacturing

infusionbagsproducesup to6,500unitsper hour.

W

henmanufacturingbags for

medical fluids, extremepre-

cisionandhighproduction

speedsareof theutmost

importance. Thesystemsproducedby

Kiefel GmbHmeet both requirements. The

companyspecialises indevelopingand

buildingsystems for thermoformingand

joiningpolymer filmsand isaglobal tech-

nology leader. Itsmachines formanufac-

turing infusionbagsbasedon the contact

weldingmethodproduceup to6,500bags

per hour,whilesystems formakingblood

bagsbasedon thehigh-frequencywelding

methodproduceup to2,500units. Inno-

vativepneumatic components from Festo

canbe found inall Kiefelmachines. The

extremely compact one-wayflow control

valvesVFOF-LE-BAHwith their three-in-one

functionnot onlysaveonassembly time,

but also reduce installationspace require-

mentsandmakemaintenanceeasier.

Festo right down the line

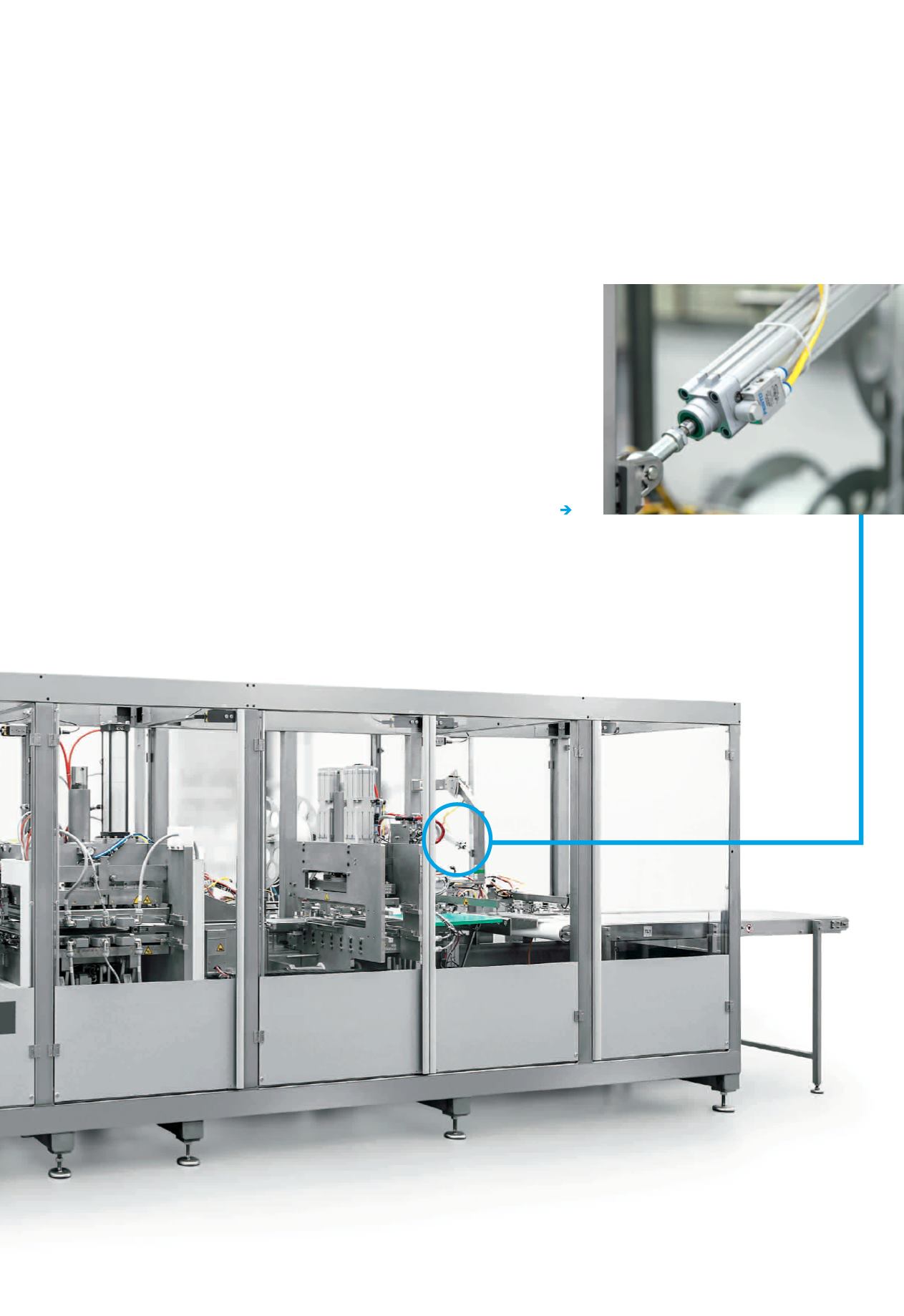

Thenewone-wayflow control valvesnot

only control thepistonspeedof cylinders,

but alsoallowan intermediatestop ina

predefinedposition. Partscanbeheldand

processed in thispositionand lowering in

theevent of the compressedair beingdis-

connectedbriefly canbeprevented. To re-

ducepotential risksasper theMachinery

Directive2006/42/EC, amanual exhaust

function isusedwhichswitches thedrive

to theenergy-freestate if the compressed

air supplyhasbeendisconnected. Along

withVFOF-LE-BAH, anumberofother Festo

componentsensureefficient pneumatic

processes inKiefel systems.These include

serviceunits for compressedair prepar

ation, valve terminalsand individual valves

and cylinders. The latter areused, for

example, tomove thegrippers for feeding

thefilmand tooperatepunching, emboss-

ing, printingandweldingequipment.

Saves installationspace:

one-way

flow control valveVFOF-LE-BAH.

1.2015

trends inautomation

Synergies

38

–

39