S

uperconductors allow objects to

be held in position contactlessly

without any control technology

and to be moved with only very

little energy. Entirely new forms of

movement can be generated that until

now seemed impossible. With the new

SupraMotion exhibits, Festo has further

extended the range of options for

positioning and movement shown to date.

With superconductor technology, effective

and constant cooling is important. The

three new applications have electrically

regulated coolers with a maximum power

rating of 80 watts.

“As soon as we get below the transition

temperature, we can precisely determine

the necessary cooling temperature with

the regulator, in accordance with the

system requirements,” explains Georg

Berner, Head of Strategic Corporate

Development, Group Holding Festo and

Project Coordinator for the SupraMotion

concepts. “If the superconductor is to

carry a greater load, we can cool it to a

lower temperature, for example.”

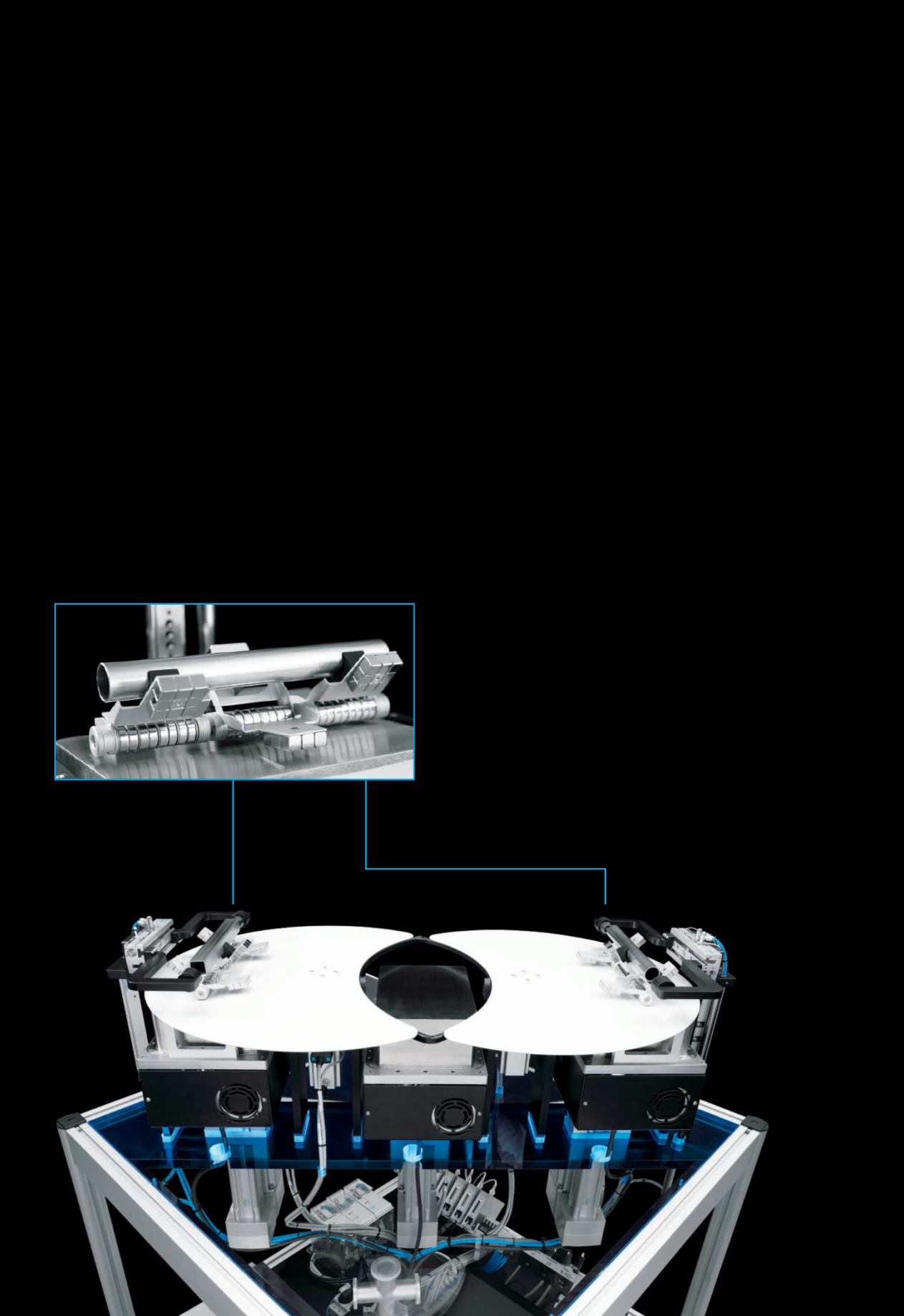

SupraJunction levitates above water

With SupraJunction, Festo demonstrates

the contactless transport of objects across

enclosed surfaces and through sluice

gates. Two carrier plates levitate above

the superconductors thanks to magnetic

rails mounted on the underside of the

plates. They transport small glass

containers around a circuit and are

transferred from one superconductor

element on one transport system to the

next element on a different handling

system.

During the contactless transfer from one

cooling tank – the cryostat – to the next,

an electromagnet attached to an electric

axis draws the carrier plate in the

effective direction of the magnetic rails.

Festo has thus for the first time realised

automated transfer from one system to

another in the horizontal plane and is

making suspended transport possible in

long process chains and across system

boundaries.

The levitating SupraGripper

also

grips and transports objects across

enclosed surfaces.