Throughout this process, the plates hover

over a flat basin of water. The carrier

system and the automation mechanism

are thus entirely separated from each

other. This protects the components

against dirt and facilitates cleaning – ideal

for applications in the packaging industry,

laboratory automation, medical

technology, or the food and

pharmaceutical industries.

SupraGripper works in separate spaces

With SupraGripper, two grippers, each

with three gripper fingers, levitate freely

above two semicircular plates. This

technology enables objects to be grasped

and transported within enclosed spaces –

a practical solution for cleanrooms or for

working in liquids, gases or in a vacuum.

The levitating effect is generated by three

cryostats, which are installed beneath the

plates and can be driven up or down. The

grippers thus either levitate above the

plates or are placed on them. In addition,

the two plates can be rotated and precisely

positioned by two rotary drives, so that

the two grippers can be transported from

one cryostat to the next.

To grasp an object, electric coils fitted on

the cryostats emit an impulse, which either

severs the stored connection to the

magnetic gripper elements or restores it

as required. This impulse causes the

individual finger elements to fold up or

down, making the grippers open or close.

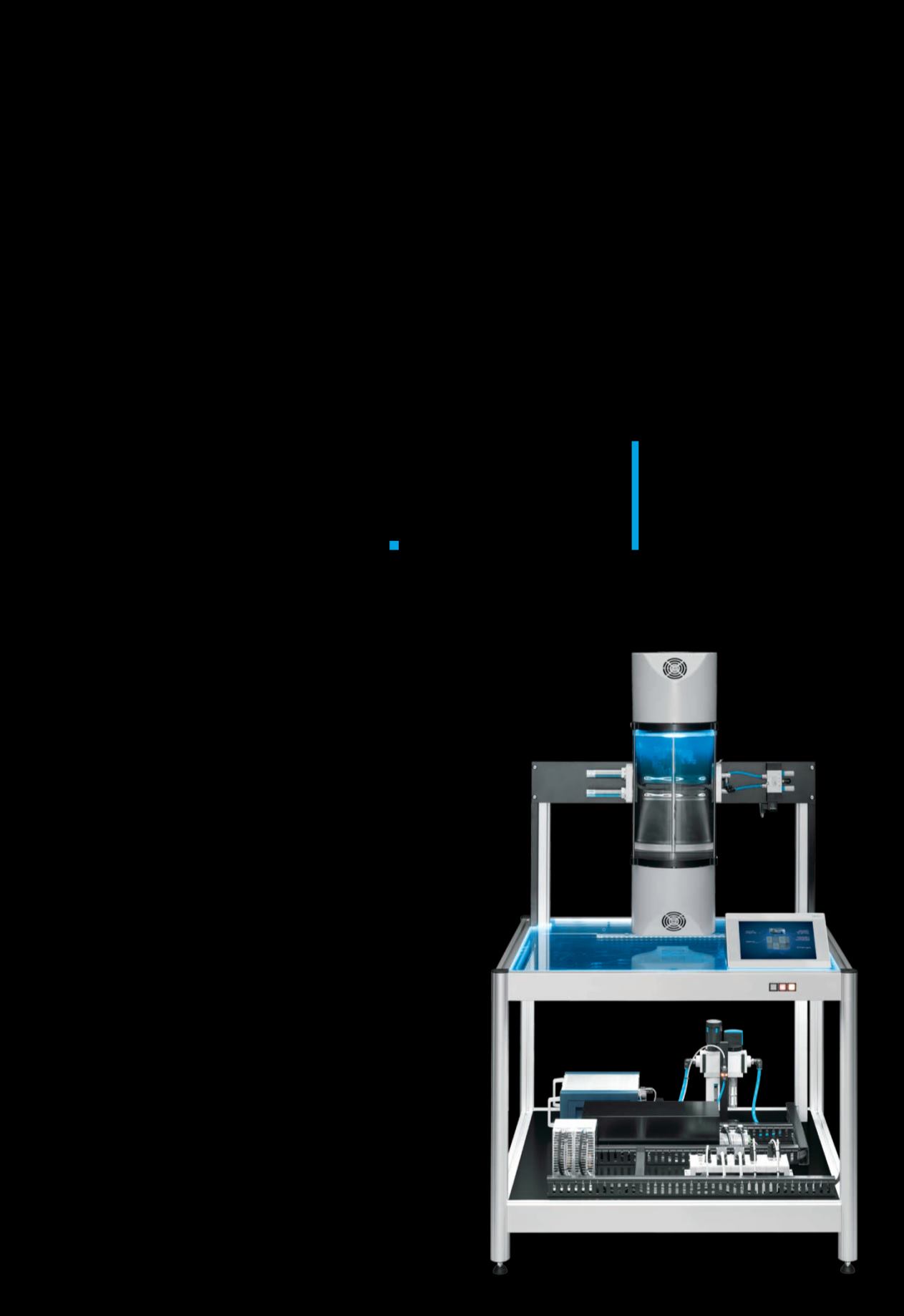

SupraTube rotates within a tube

The SupraTube exhibit shows how a

controlled movement can be executed

within a tube without direct intervention

from the outside. A round cryostat with

superconductors is attached to the

outside of each end of a liquid-filled glass

tube. Inside the vertical tube is a magnetic

puck that is virtually tethered to the two

cryostats with a levitation gap of around

five millimetres and is initially suspended

beneath the upper cryostat. A ring magnet,

which surrounds the cryostats, is set to

rotate by a stepper motor, and transfers

the motion to the suspended magnet. The

magnet is repelled from the cryostat by an

electrical impulse and drifts downwards in

a spiral motion. At the lower end, it is

captured once more and centred by the

superconductor in the other cryostat.

In a slightly modified SupraTube

configuration, drive units with

superconductor magnetic couplings can

be fitted along the longitudinal axis of the

tube in order to draw a cleaning unit

through it, entirely free of contact.

Alternatively, the contents of a closed

container – such as hazardous substances

or explosive gases – can be set in

rotation.

Research for the production of the future

After several years of intensive research

and three years of experience in this field

at trade fairs, Festo is now meeting with

partners and customers to discuss and

explore their specific ideas for application.

“We have now created 12 different

concepts that have really inspired our

customers and given them lots of ideas

for new applications,” says Georg Berner.

He and his team are currently working on

getting the first pilot projects off the

ground.

SupraTube

executes a movement inside a tube

without direct intervention from the outside.

More information on

superconductor technology

and the new projects

can be found at

www.festo.com/supramotionIssue 30

trends in automation

Compass

16

–

17