C

asting resins protect high-quality

electronic components against

undesirable penetration by dirt

and moisture. Precise and

reliable dispensing technology is essential

for the automatic application of these

resins. bdtronic GmbH, a company

located in Southern Germany, is one of

the world’s leading suppliers of

dispensing systems, including complete

systems for automating the assembly and

production of electronic components.

bdtronic has now worked with Festo on a

ground breaking project to expand its

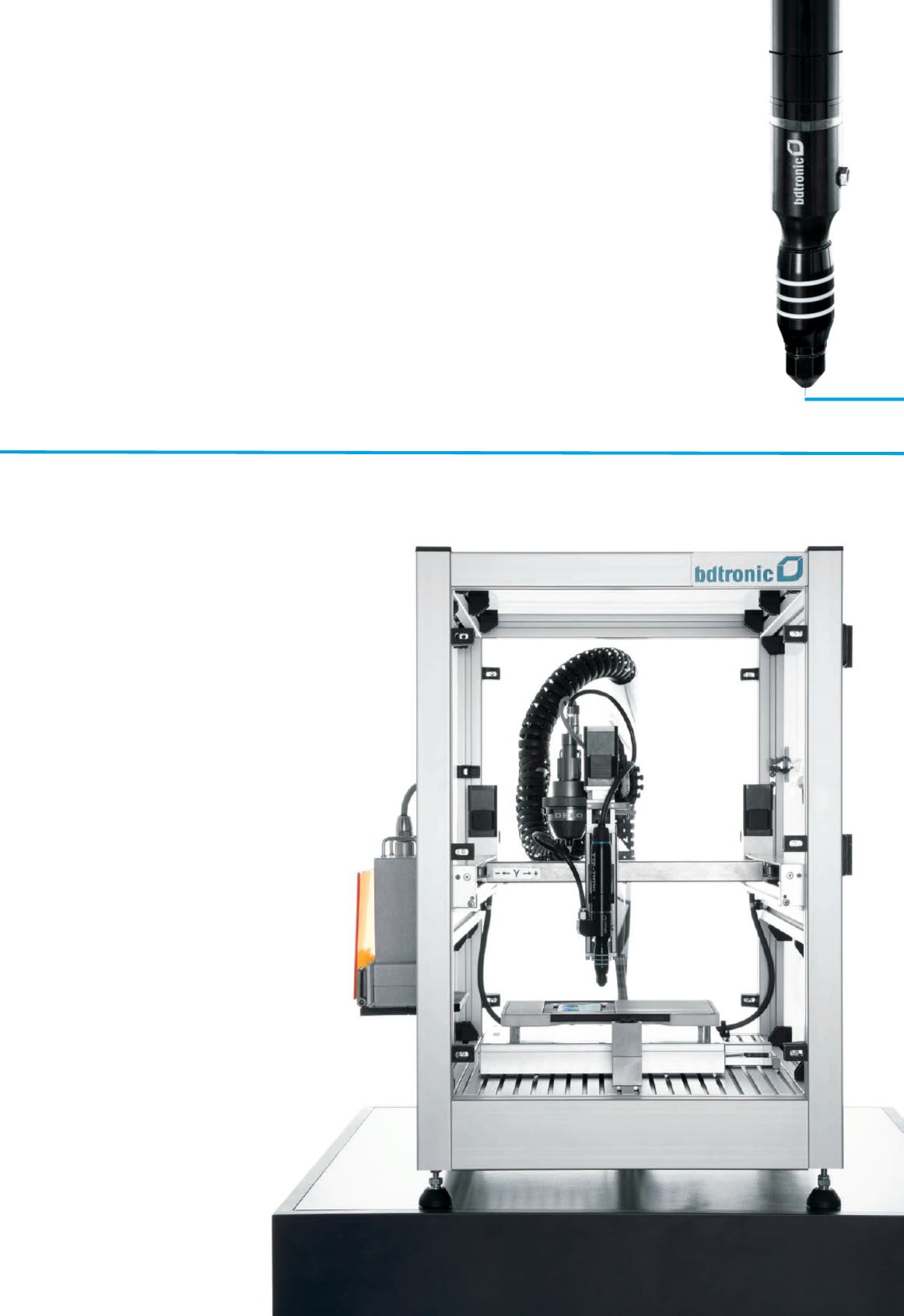

product portfolio. The new mini-dis from

bdtronic, based on the compact handling

system YXMx, opens up another field of

application in the front-end processing of

electronic and telecommunications

products. The integrated CECC-X

controller allows curved travel paths, thus

making it possible to produce even

complex casting patterns. Designed as a

space-saving and flexible desktop

application, the new complete solution

from Festo facilitates cost-effective

production of extremely short production

runs.

From car parking sensors through to smartphones

and electric toothbrushes,

sensitive electronic components need protection against undesirable substances.

That is why special casting resins are used. The “mini-dis” desktop machine

from bdtronic allows high-precision dispensing processes in a very small space –

thanks, among other things, to the compact handling system YXMx from Festo.

Perfect curves

Dispensing casting resin