Issue 30

trends in automation

Synergies

30

–

31

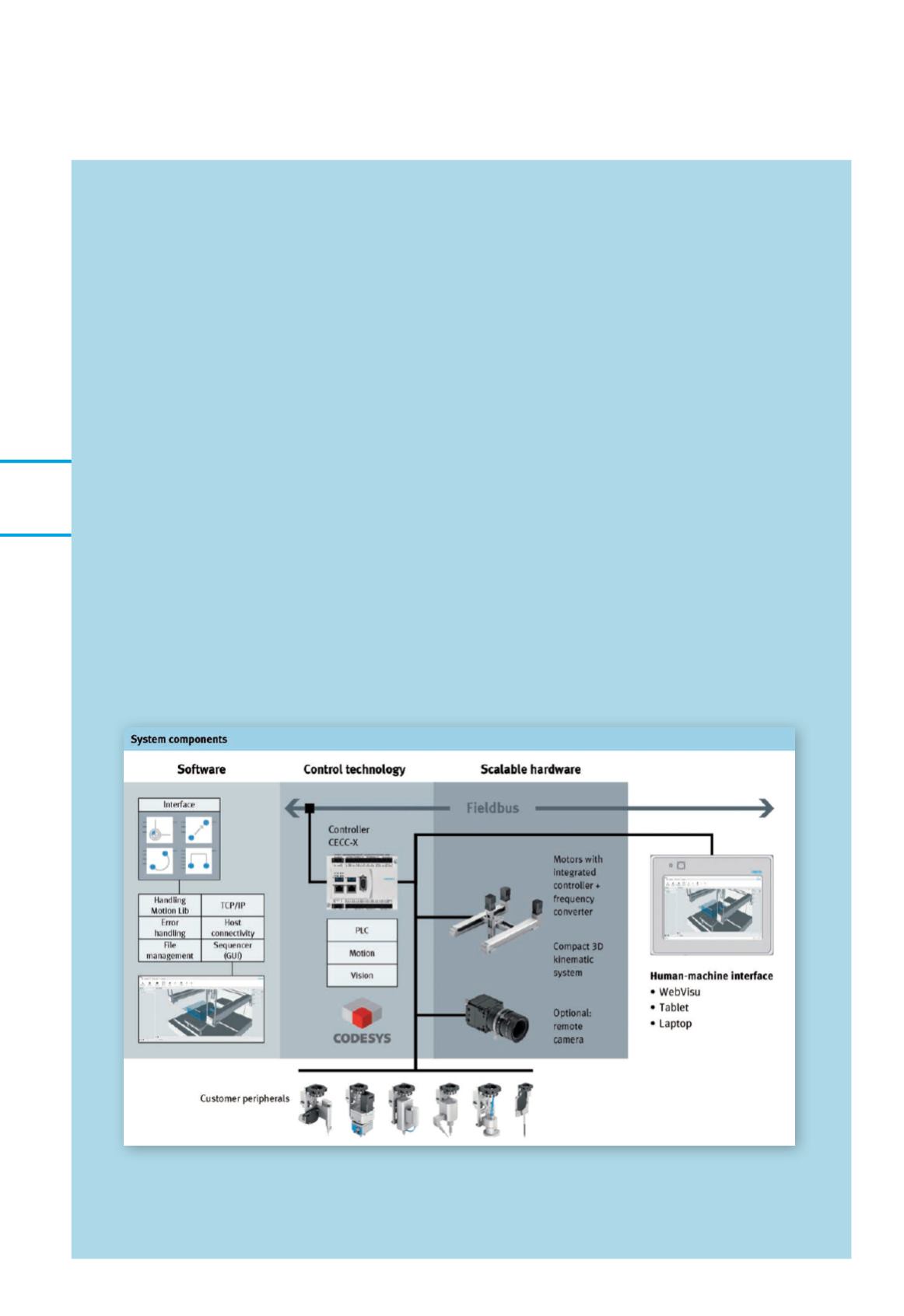

Kinematics, controller and software in one package

Compact handling systems for moving workpieces or tools help machine and system builders in

electronics and small parts manufacturing to significantly reduce their engineering costs – and they get a

cost-effective system thanks to standard components. Predefined function modules from the software

library and intuitive application programming with the sequencer simplify programming and commissioning.

The system kit from Festo consists of perfectly matched components and functions from a single source.

These components can be used to simply combine complete systems, consisting of kinematics, controller

and even software. Systems of this kind open up entirely new potential for savings. They enable machine

and system builders to concentrate fully on their core business.

Programming and commissioning with the predefined function modules of the Handling Motion Lib is quick

and easy. The following functions are possible: parameterisation, reference travel and jogging operation

for the interfaces for communication with host systems, file management and a message system for error

handling and sequence processing.

Included in the system kit is a compact controller CECC-X. This allows numerous functions to be carried out

in very small spaces. It contains a range of predefined interfaces to a master control system – including the

OPC-UA interface for Industry 4.0.