bdtronic GmbH

Ahornweg 4

97990 Weikersheim

Germany

www.bdtronic.deArea of business:

Production of complete solutions in

the areas of dispensing technology,

plasma pre-treatment, hot sealing,

impregnation technology and

process automation.

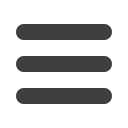

(A) On the move:

the compact planar

surface gantry provides maximum working

space coverage. And it can travel to any

required position within the working space.

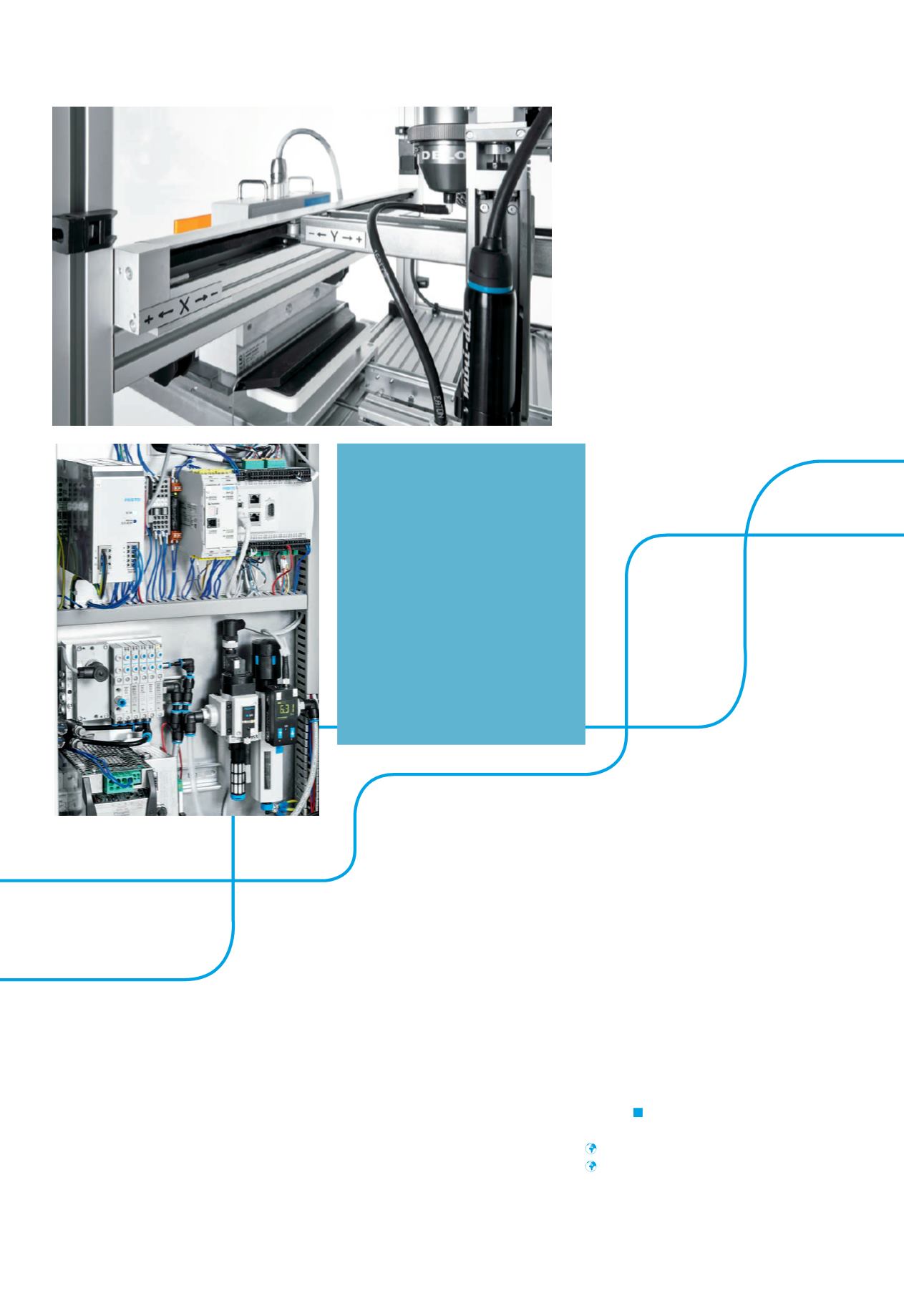

(B) Just as compact as the handling system

is the interior of the control cabinet, with a

controller CECC-X (top right), a valve

terminal VUVG (bottom left) and a service

unit from the Festo MS series (bottom right).

(A)

(B)

With its compact dimensions, the

controller is a perfect match for the planar

surface gantry EXCM-30, which offers

many functionalities for working loads of

up to 3 kg. The gantry provides maximum

working space coverage. And it can travel

to any required position within the working

space.

Perfectly matched

Festo has designed its compact handling

systems as a kit with perfectly-matched

standard components. The bdtronic

mini-dis uses a planar surface gantry

EXCM-30 with additional Z-axis EGSK as a

kinematic mechanism including the

controller CECC-X. It also includes a

comprehensive software package for

simple programming and commissioning,

which is an integral part of the Festo

complete solution. Having a large number

of functions available in a very small

space avoids the problems of both under-

and over-dimensioning. The controller

software, based on CODESYS, offers the

most important basic functions that are

needed to program travel paths even

without an in-depth knowledge of

programming. The controller interfaces

allow the compact USB cameras, sensors,

actuators and valves all to be connected.

All of this results in great efficiency and

saves considerable amounts of time and

money.

www.festo.com/hgo www.festo.com/cecc