Issue 30

trends in automation

Festo worldwide

34

–

35

Tension guaranteed

Producing bandages using the fluidic muscle DMSP

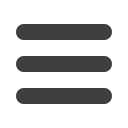

Wernli AG was founded in 1932 and was the first textile manufacturer in the world to produce coloured dressing materials. Today, it

is cohesive and adhesive elastic bandages, as well as compression bandages, that are securing Wernli a leading position in the

global market. The company processed 336 tons of yarn in 2014. Laid end to end, the finished bandages would reach over 51,000

km. 85% of the 10 million bandages produced each year are exported. According to Ruedi Leutert, Head of Prework/ Weaving,

Development and Yarn Purchasing at Wernli, for long-term success, you need more than just product innovations. The flexibility to

custom manufacture small-scale series and deliver quickly is also important. New efficiencies are being identified all the time and

implemented gradually. This was the case with the looms for the Bi-Flex type bandages, which are elastic both lengthways and

crossways. The warp beams from which the yarn is continuously unwound must move under constant tension. Without the use of

compensating lead weights, the speed of the warp beams would increase as more yarn is unwound and produce an unevenly

elastic bandage fabric. The weights, which weigh between 2.5 and 15 kg, previously had to be hung manually on the warp beams

by employees. The fluidic muscle DMSP from Festo has revolutionised this complex process.

The innovative pneumatic drive has clear advantages for this application compared with a conventional

pneumatic cylinder. Since there is no need for a piston rod, friction and therefore the stick-slip effect – the

jerking motion that can occur while two solid objects are rubbing against each other – are not a problem.

This means that, together with the precise closed-loop control provided by the fluidic muscle DMSP, the

yarns are now optimally tensioned. This guarantees the high quality of the finished bandages.

Without the weights used previously, the quality of the products is improved and the risk of

accidents is reduced. A further advantage is that the fluidic muscle needs much less

installation space compared with the weights.

www.festo.com/fluidicmuscle www.weroswiss.comClever solution:

thanks to the fluidic muscle there is no longer

a need for the weights and the yarn tension can be set precisely.

Switzerland